Minimal quantity lubrication technology is a new cooling and lubrication technology in recent years. Compared with traditional pouring type, trace lubricants are accurately delivered to workpieces/tools that need lubrication and cooling in an effective supply mode, eliminating the supply of ineffective positions, which can make lubricating oil more stable. The amount of lubricant used is reduced by more than 90%, thereby improving the cooling and lubricating effect, solving the problems of large amount of lubricant used, large ineffective supply, serious environmental pollution and high investment cost, and realizing clean processing and green manufacturing.

In the micro-lubrication technology, the micro-lubricating agent requires good lubricity during use, good extreme pressure and anti-wear performance, and less oil fumes during processing. Screening suitable micro-lubricant formulations is a challenging task. After screening, evaluation and experiments, among various lubricant materials, phosphorus-containing organic compounds, especially phosphate esters, are a qualified choice, and phosphate esters have the following characteristics. Extreme pressure and wear resistance of phosphate ester: Phosphate ester chemically reacts with metal (especially Fe) on the metal surface to generate iron phosphide and ferrous phosphate. These inorganic salts are deformed by plastic flow under the action of frictional heat and pressure , falls into uneven low points on the surface, increasing the contact area, lowering the pressure point, and providing boundary lubrication of the metal surface. Therefore, it has better extreme pressure and wear resistance. Corrosion resistance of phosphate esters: In the process of metal processing, phosphide first adsorbs on the iron surface to form an organic iron phosphate film, and then C-O bonds are broken under extreme pressure and frictional heat; the organic iron phosphate film can be After further reaction and decomposition, an inorganic iron phosphate reaction protective film is formed, so that there is no direct contact between the metal and the metal, so as to protect the metal surface, so it has an excellent corrosion inhibition effect. Flame resistance of phosphate esters: Phosphate esters have an important distinctive feature of low heat of combustion, which is due to the presence of phosphorus in the molecule and the structure of the bonds. The heat of combustion of trialkyl phosphate is lower than 7800Kcal/kg, while that of mineral oil and other synthetic hydrocarbons is around 9500kcal/kg. Less heat release does not support combustion. When the fire source leaves, the phosphate ester automatically extinguishes the fire. Phosphate has three characteristics: good extreme pressure and anti-wear performance, excellent corrosion resistance, and strong flame resistance. Therefore, phosphate esters are selected as an important part of the base formulation of trace lubricants. Research on the Application of Phosphate Esters in Minimum Quantity Lubrication After laboratory and application verification, the use of phosphate esters with a mass ratio of 3% to 5% in the formulation of trace lubricants can significantly reduce friction, improve extreme pressure and anti-wear performance, delay the corrosion of processed metals, and reduce oil fume during processing. When producing raw materials for synthetic trace lubricant components, attention should be paid to the composition and molecular structure of phosphate esters. Therefore, suitable phosphate esters are often selected in the process of guiding research and production, or phosphoric acid (or phosphorus pentoxide) is used in the synthesis of complex esters. As a catalyst, no catalyst separation is performed after the reaction is completed, and a polyester/phosphate complex ester that is beneficial to the final product is formed.

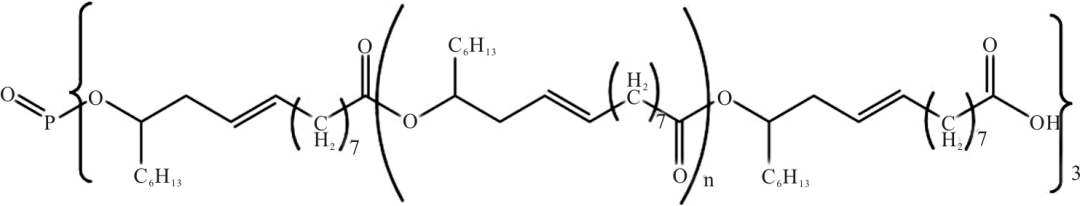

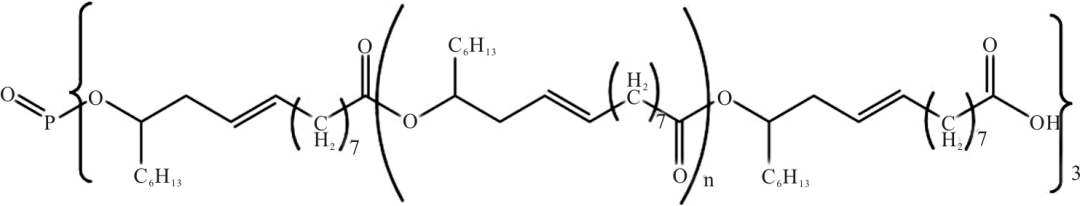

The research content will be further elaborated below with the invention patent that specifically guides production, such as Example 6 of the invention patent environmental protection trace lubricating oil. Mixed with mannitol oleate phosphate, trimethylolpropane trioleate, ethyl oleate, isotetradec/pentanol, oleoyl sarcosine, triethanolamine borate in a mixer until transparent An environmentally friendly trace lubricant is prepared. Among them, mannitol oleic acid phosphate is prepared by adding mannitol, oleic acid and phosphoric acid into the reaction kettle, filling with nitrogen to convert the air in the reaction kettle, and carrying out esterification reaction. Application experiment: The above trace lubricating oil is applied to the machining center for milling aluminum alloy parts. The model of the trace lubrication system used is: KS-2107 (two energy-saving nozzles); Circulating lubrication and cooling). In the process of studying the minimal amount lubrication technology, our team broke through the conventional catalytic process in the polyester synthesis process, abandoned the traditional idea of using high-efficiency Lewis acid (sulfuric acid, sulfonic acid) catalysis and cation exchange resin/molecular sieve and other catalysts for easy separation process, and adopted difficult-to-separate catalysts. Phosphoric acid is used as a catalyst to catalyze the reaction. By controlling the catalytic conditions, reaction temperature, reaction time and other influencing factors, the catalyst is not separated after the reaction is completed, and a polyester-phosphate compound ester additive suitable for processing under extreme conditions is prepared, which greatly reduces the compound ester. The production cost eliminates the consumption of chemicals and hydropower resources for separating catalysts, and the benefits of energy saving, emission reduction and environmental protection are remarkable. Invention patent: a degradable trace lubricating oil and its preparation method. In the synthesis of polypentaerythritol methacrylate oleate, the catalyst is preferably phosphoric acid with a concentration of 10% to 85%. The benefits of choosing phosphoric acid as a catalyst, the phosphoric acid ester generated by the esterification reaction of phosphoric acid and pentaerythritol is an excellent extreme pressure resistance. It is a grinding agent that does not need to separate the catalyst, and can be used in a trace amount of lubricating oil to improve the extreme pressure and anti-wear performance. Step 1: Weigh pentaerythritol, methacrylic acid and oleic acid according to the specified molar ratio and add them into the polymerization kettle, add phosphoric acid with a concentration of 50% to carry out esterification reaction to prepare pentaerythritol methacrylic acid oleate. Step 2: adding an initiator into the polymerization kettle to carry out addition polymerization to prepare polypentaerythritol methacrylate oleate. After adding zinc stearate to butyl oleate, heating and stirring until completely dissolved, polypentaerythritol methacrylate oleate, butyl oleate, and isomeric trace lubricating oil were weighed. Tridecyl alcohol phosphate is respectively added into a stirrer and stirred to prepare a degradable trace lubricating oil that can be degraded by the above method. After adding zinc stearate to butyl oleate, heating and stirring until completely dissolved, polypentaerythritol methacrylate oleate, butyl oleate, and isotridecyl phosphate were weighed and added to a stirrer and stirred to prepare a Degradable In order to achieve the requirements of good friction and extreme pressure anti-friction properties of trace lubricants, it is often necessary to design a polyester-phosphate compound ester with a specific structure. For example, patent ZL21310354862.X discloses the molecular structure of polyricinoleate phosphate, see figure below.

Application of Minimum Quantity Lubrication Technology The phosphoric acid ester-containing trace lubricant technology developed by our team has been successfully applied to many metal processing enterprises. In the process of metal processing, it saves more than 90% of the lubricant usage for these enterprises, and achieves significant energy saving, emission reduction and environmental protection effects. . Currently, there are more than 1,000 metal processing enterprises applying the MQL technology researched by this team: CRRC, AVIC, Aluminum Corporation of China, China Railway, Gree Electric, Midea, Foxconn, Baowu Steel, Shanghai Electric, etc. The user feedback is good, which greatly reduces the user's metal processing cutting fluid usage, reduces the use cost, reduces the harm to the environment and workers, improves the quality of the processed metal surface, and improves the production efficiency at the same time. Customer application case: 5% polyester-phosphate compound ester is used as anti-friction and extreme pressure anti-wear agent in the formulation of trace lubricants, which is applied to the technical renovation of machine tools in an aviation parts processing enterprise. Machine tool model: VL-0855CNC machining center, processing workpiece specifications: 300mm×10mm×0.3mm aviation aluminum alloy parts, the minimum quantity lubrication system used is the minimum quantity lubrication device produced by the company; traditional machining uses cutting fluid (concentration of about 5%) ) for lubricating cooling. Table 3 shows the comparison before and after the transformation of the MML technology. Conclusion Due to the action of frictional heat and extreme pressure, phosphate ester can form an organic/inorganic chemical protective film on the metal surface, which can play the characteristics of extreme pressure, anti-wear and anti-friction, preventing corrosion and preventing combustion. The effect of adding a certain percentage of phosphate ester in trace lubricants on the friction coefficient and extreme pressure and anti-wear effect is very obvious. Therefore, when designing the formulation of trace lubricants, the addition of phosphate esters as antifriction and antiwear additives, corrosion inhibitors and flame retardants should be fully considered, which can effectively enhance the extreme pressure, antiwear and lubricity of trace lubricants. It can greatly reduce the use of trace lubricants in the actual processing process, and at the same time effectively prevent smoke during processing and improve the surface quality of metal processing, optimize the metal processing process links, and is of great significance to energy saving, emission reduction and environmental protection in the metal processing industry.