Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() May 04, 2023

May 04, 2023

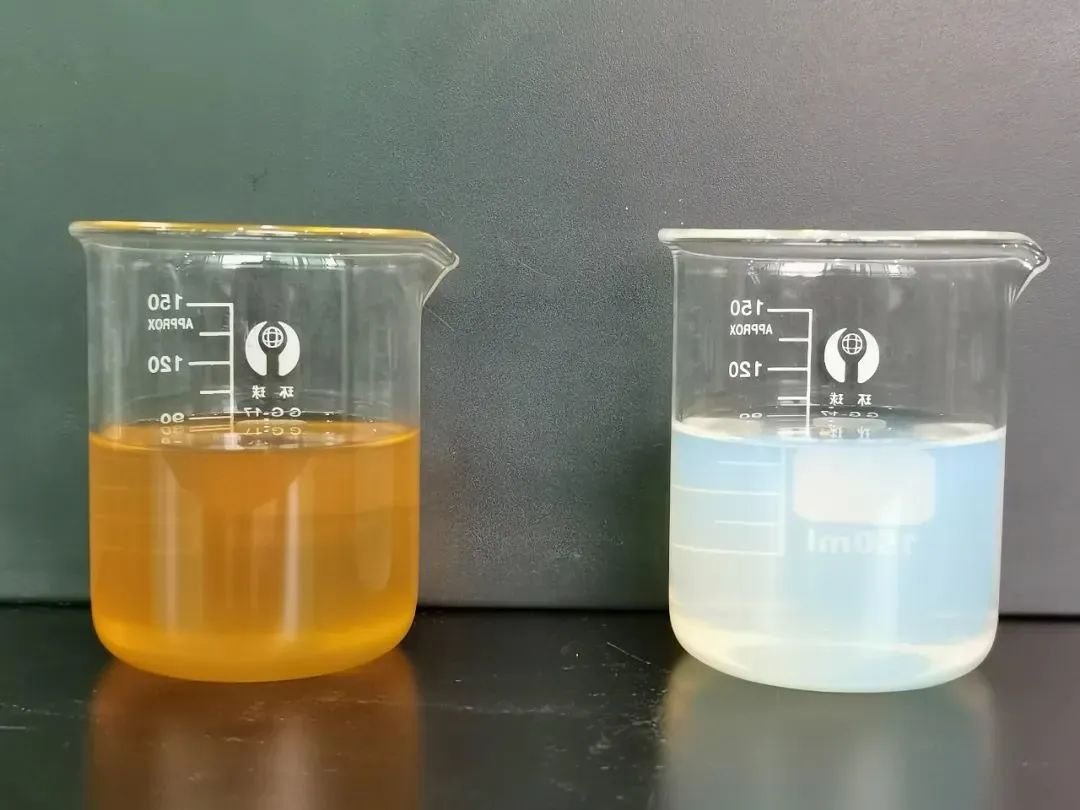

Water-based cutting fluid should be used within a certain concentration range, otherwise it not only cannot fully exert its function, but also causes various troubles. Using at excessively high concentrations not only increases costs, but also results in sludge formation due to the mixing of oil spills, making filtration difficult. If the concentration is too low, it will cause cutting performance problems, such as shortened tool durability and deteriorating dimensional accuracy. In addition, if the concentration is too low, the rust resistance will also decrease, causing corrosion. And the cutting fluid is also prone to decay. Therefore, maintaining the specified concentration of water-based cutting fluid is a very important task. Doing a good job in concentration management can extend the lifespan of cutting tools and usage fluids, reduce costs, and thus reduce waste liquid emissions.

Water-based cutting fluid is diluted with water as the diluent. If the diluted water contains a large amount of sodium chloride and sulfate, it is not only easy to cause the use of liquid corruption, but also reduces its rust resistance. Therefore, it is hoped that diluted water has better water quality than tap water. If the concentration of the liquid used is extremely thin or its composition is unbalanced, its rust prevention performance will inevitably decrease. In this sense, rust resistance is an indicator of the deterioration of the liquid used. When the rust resistance decreases, the general measure taken is to supplement the original solution to increase the concentration. In situations where the rust prevention time of water-based cutting fluid is short, the workpiece stays between processes for a long time, or the weather conditions suddenly change in an environment prone to rusting, rust prevention oil should be applied in advance to prevent corrosion.

The frequent use of liquid replacement is due to corruption. The use of water-based cutting fluid is contaminated due to oil leakage and the mixing of chips, causing abnormal microbial growth and decay. The process is:

① Mild putrefaction odor (acid putrefaction) occurs;At this point, it is necessary to change the usage fluid. The spoilage of water-based cutting fluid is the result of abnormal microbial reproduction, with aerobic bacteria being the most common and anaerobic bacteria also present. During use, the proliferation of aerobic bacteria reduces oxygen in the liquid, while on weekends and rest days, the liquid stops flowing and anaerobic bacteria continue to multiply, causing the liquid to smell. The original solution of water-based cutting fluid is heated and sterilized with fungicides during the manufacturing process. However, during use, diluted water, processed parts, dirt around the machine tool, hands of operators, and bacteria in the air are mixed in. In addition, the use of the fluid has appropriate temperature and nutrients such as carbon water compounds, minerals, proteins, etc., causing bacteria to continuously reproduce and even cause the use of the fluid to decay and deteriorate.

The above is the What issues should be paid attention to in the daily management of water-based cutting fluids? we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+8613783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.