Environmental protection and energy saving have become the theme of the times for all mankind, and the development of some new pollution-free energy-saving and environmental protection additives has been the call of the times and the market. Especially for water-based cutting fluids, energy saving and environmental protection are more urgent and necessary. The birth of water-soluble organic molybdenum products is in response to the needs of this era and market. It has outstanding anti-wear and anti-friction properties, its use can effectively reduce the amount of other extreme pressure anti-wear agents containing sulfur, phosphorus and chlorine, and greatly reduce the negative impact of water-based cutting fluid on the human body and the harm to the environment. It is believed that this product, which integrates excellent anti-wear, energy-saving and environmental protection properties, will be more and more recognized and respected by peers in the lubrication industry and the market.

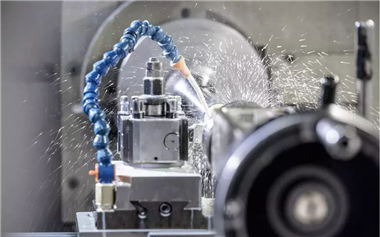

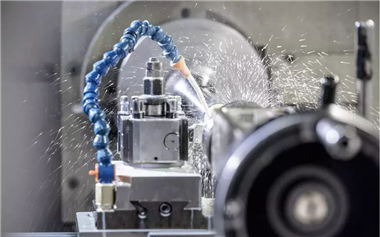

1. Application of water-soluble molybdenum extreme pressure agent Water-soluble molybdenum extreme pressure agent is a high-efficiency extreme pressure and anti-wear for lubricants such as water-based lubricants, water-soluble oils, emulsified oils, emulsified liquids, saponified oils, saponified liquids, semi-synthetic lubricants, fully synthetic lubricants, and metalworking coolants. Additive; also suitable for fire resistant hydraulic fluids. Especially suitable for heavy load extreme pressure occasions and harsh working conditions. Water-soluble molybdenum extreme pressure agent is widely used in turning, drilling, boring, milling, planing, broaching, sawing, grinding, grinding, tapping, tapping, gear hobbing, gear shaping, stamping, blanking, It is suitable for lubricating and cooling occasions of metal cutting, metal plastic processing and fire-resistant hydraulic occasions such as wire drawing and machining center.

2. Performance characteristics Water-based lubricants have many advantages such as environmental protection and energy saving, cleaning, cooling, non-combustibility, easy observation of workpieces, and not easy to spoil and deteriorate. However, due to poor lubricity, the use of water-based lubricants has always been restricted. The use of water-soluble molybdenum extreme pressure agents can effectively solve the problem of water-based lubrication. The problem of poor lubricity of lubricants promotes the rapid development of water-based lubricants. 1) The water-soluble molybdenum extreme pressure agent completely overcomes the shortcomings of traditional water-soluble molybdenum on the market - poor water solubility, opaque and unstable after water solubility, and excellent water-soluble transparency. 2) Outstanding extreme pressure and anti-wear performance, high load-bearing performance and boundary lubrication performance. 3) The basic lubricating performance of high-efficiency lubricants, the strong adsorption and antifriction performance of oil-based agents, and the super anti-wear performance of extreme pressure antiwear agents are three-energy-integrated load additives, which can greatly improve lubricity and reduce friction and wear. , Prevent sintering, improve machining accuracy and finish, and effectively protect tool molds. 4) It has good lubricity, anti-friction performance, extreme pressure and anti-wear performance at low temperature, medium temperature and high temperature. 5) It better solves the disadvantage that extreme pressure anti-wear agents on the market only work at high temperature. This product plays the role of efficient lubricant at low temperature, and plays the role of oily enhancer at medium temperature. Friction reduction, high temperature Plays the role of extreme pressure anti-wear agent. 6) Excellent high-speed scratch resistance, high temperature stability, and anti-sintering performance, the formed adsorption conversion film still has a certain anti-wear effect above 750 °C. 7) Cleaning functions such as wetting, penetration, scouring, and chip removal. Excellent cooling and cooling performance. 8) The water-soluble molybdenum extreme pressure agent has moderate color and excellent water solubility, and is widely used in water-based cutting lubricants, water-based metal working fluids, and fire-resistant hydraulic fluids. 9) It can be used as a load additive or directly mixed with water as a water-based lubricating fluid. 10) Maintain high-efficiency extreme pressure and anti-wear effect at very low concentration. 11) Water-soluble molybdenum extreme pressure agent has a certain anti-rust effect.

3. Physical and chemical indicators Project indicators Appearance red liquid Specific gravity greater than 1.0 odor slightly pleasant PH value 7.5—9.5 4. How to use 1) When this product is used as a load additive, in the concentrated lubricating fluid system, the recommended dosage is 2%--25%. 2) When this product is used as a load additive, in the water-based lubricating working fluid system, the recommended addition amount is 0.5%--8%. 3) Water-soluble molybdenum extreme pressure agent is also a high-efficiency lubricant, and can also be used in stock solution for direct metal processing. 4) Stir this product before use, and add it into the system by slow mixing and full stirring. 5) This product can also be directly mixed with water as a lubricating coolant. The recommended dilution ratio is 20-100 times. 6) When using this product, the higher the concentration, the stronger the function. 5. Matters needing attention 1) Due to the diversification of the original lubricating system formulation, it is recommended to conduct a small test before use to determine the compatibility, compatibility and stability of the extreme pressure antiwear agent and the system. 2) It is recommended to use low hardness water or softened water to prepare the working fluid to ensure the super performance of this product. 3) It is strictly forbidden to enter water and other impurities, and it is strictly forbidden to store in a ventilated and dry place.

![]() April 10, 2022

April 10, 2022