Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2022-03-20

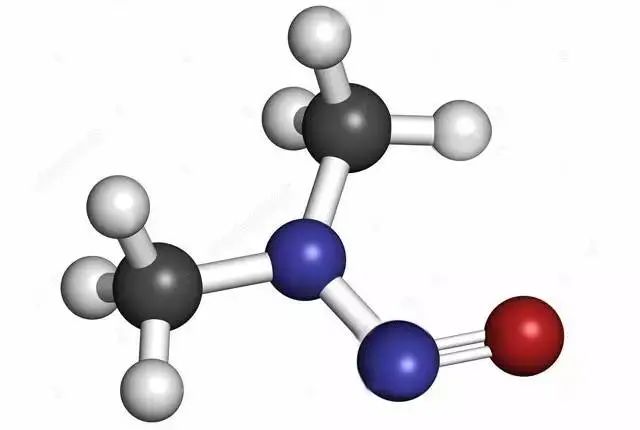

If metalworking fluids are stored for a long time, nitrosamines will be produced. Nitrosamines are carcinogens. Water-based metalworking fluids will slowly generate nitrosamines during long-term storage. In addition, containers containing metalworking fluids may also Causes the formation of nitrosamines. Manufacturers and marketers need to check with the drum supplier to ensure that the supplier does not use sodium nitrite in the final rust rinse. Nitrite in rust inhibitors can react with secondary amines in metalworking fluids to form nitrosamine carcinogens. Nitrogen oxides in the air also react slowly with metalworking fluids to form nitrosamines. Nitrosamines in metalworking fluids are a threat to the environment and operators, so it is necessary to do a good job of recycling waste liquids.

Metalworking fluids may incorporate metal chips, such as nickel, chromium, etc., during processing. In addition, polycyclic aromatic hydrocarbons may be generated during the use of metalworking oils under the action of high temperatures.

Skin Contact

Metalworking fluids can cause contact dermatitis through skin contact. When workers replace metal workpieces, if they do not take effective hand protection, they can directly contact the metal working fluid on the surface of the metal workpiece.

America

According to the REL of "What You Need To Know About Occupational Exposure to Metalworking Fluids" published by NIOSH in 1998, the MWFs thoracic particulate matter limit is 0.4mg/m3 and the total particulate matter limit is 0.5mg/m3, applicable to all metalworking liquid. The detection method of metal cutting fluid is in accordance with NIOSH 5524, and the detection method of oil mist can be in accordance with NIOSH 5026.Share to:

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+8613783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.