Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

2022-09-29

With the rapid development of modern machinery manufacturing industry, the continuous innovation of cutting technology and cutting process has put forward higher requirements for the performance of cutting fluid. Especially in recent years, environmental protection and human health have increasingly become the focus of attention of the whole society, and cutting fluid will cause pollution and damage to the environment and human body, so the use of cutting fluid and waste liquid treatment have been increasingly restricted by environmental regulations. In developed industrial countries, the amount of smoke generated during machining with cutting fluid is also strictly limited. Some cutting fluid waste liquid and chips with cutting fluid are required to be treated as toxic materials, and the cost of treatment is increasing. In order to meet the requirements of social development, some new features have emerged in the development of modern cutting fluid technology.

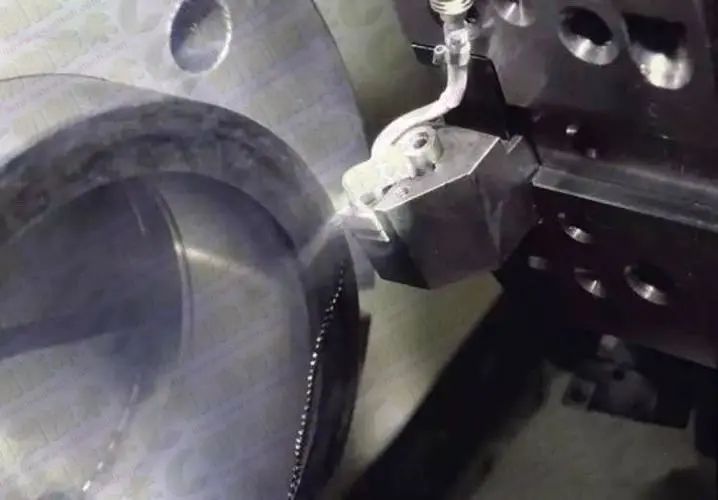

In this respect, liquid nitrogen cooling is the most studied. Nitrogen is the most abundant component in the atmosphere. As a by-product of the oxygen production industry, liquid nitrogen is very rich in resources. With liquid nitrogen as cutting fluid, it will volatilize directly into gas and return to the atmosphere after use, without any pollutants. From the perspective of environmental protection, it is a promising alternative to cutting fluid. One of the ways to use liquid nitrogen cooling is to spray liquid nitrogen as cutting fluid directly into the cutting area. Another method of using liquid nitrogen cooling is indirect use, that is, instead of spraying liquid nitrogen directly into the cutting area, liquid nitrogen is stored in the square box on the upper part of the polycrystalline CBN tool, which is input from the inlet and output from the outlet. When turning sintered silicon nitride in this way, the tool life is extended by 10 times and the wear is reduced by 1/4.

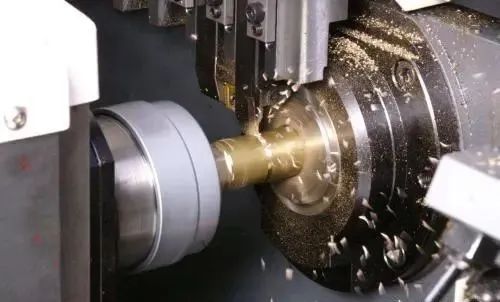

At present, there are strict regulations in foreign countries that restrict the use of some cutting fluids, and the cost of waste liquid treatment is very high. For example, Germany spends about 1 billion marks on waste liquid treatment every year. Therefore, in the United States, Germany and other industrial developed countries are vigorously advocating the use of dry cutting technology. In some applications, chilling gas and cyclone sprayer can be used to reduce cutting temperature, such as jet cooling. It is predicted that in the future, if high-performance tool materials and chip breaking grooves with excellent chip removal performance are used together with cooling gas, the goal of no longer using cutting fluid can be achieved.

Share to:

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+8613783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.