Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

![]() November 21, 2022

November 21, 2022

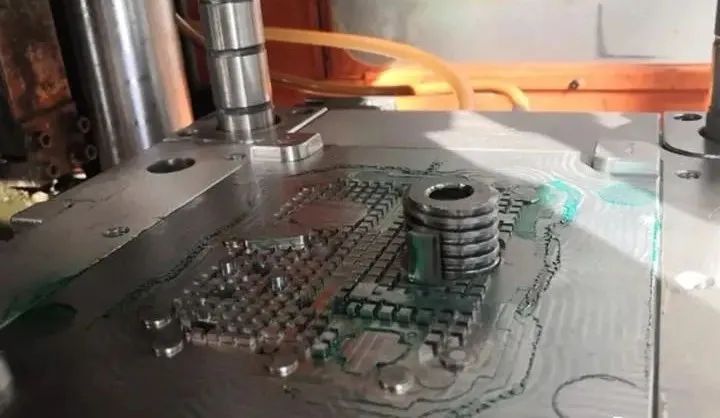

Whether the demoulding of injection products is smooth or not depends on the reasonable design of the mold structure and the reasonable selection of the process parameters of injection products. In injection molding production, due to the fluctuation of process conditions, it is sometimes difficult to demould products.

No matter what kind of release agent is used, the amount of release agent used during spraying shall be subject to the successful release of products, and shall be used as little as possible. Excessive amount of spray release agent will affect the appearance quality of the products, causing oil spots or darkening of the product surface, especially for products with high transparency requirements. Sometimes, the application is prohibited. If the apparent quality of the products is required to be high, the release agent can only be applied to the parts where it is difficult to demould the products.

The above is the Why does the injection mold release agent stick to the plastic parts? we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry

Send Inquiry

Mr. James

Tel:0086-371-58651986

Fax:

Mobile Phone:+8613783582233

Email:sales@cn-lubricantadditive.com

Address:No.11 Changchun Road, High-Tech Zone, Zhengzhou, Henan

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.