The selection and replacement of industrial Gear Oil must avoid the 2 major misunderstandings! Main body

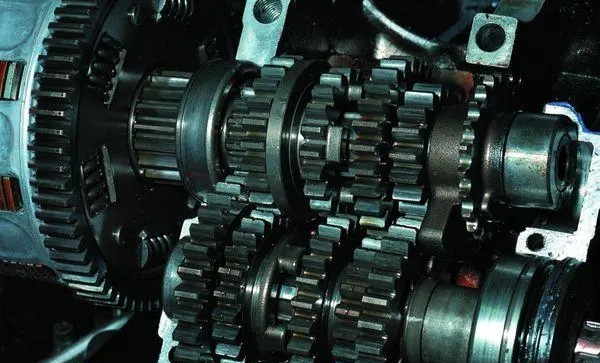

The selection and replacement of industrial Gear Oil must avoid the 2 major misunderstandings! Main body Industrial gear oil is one of the key factors to maintain the normal operation of the gear system, and some users are still troubled by the selection of industrial gear oil, in the face of different equipment models and different working environments, how to choose a suitable oil?

What mistakes should be avoided in oil selection?

High price equals good performance? People usually think that "expensive" means "good performance", but this statement is not completely appropriate in industrial gear oil. The industrial gear oil on the market is generally divided into three kinds according to the different base oils: mineral type, semi-synthetic and fully synthetic, the general pricing of fully synthetic oil is relatively expensive, the cost difference is mainly due to the complexity of the manufacturing process and the product maturity is different, so the price gap can not represent the difference in oil lubrication performance. Of course, it is not possible to use low price lubricating oil, low price lubricating oil may be poor quality, unable to provide sufficient lubrication and protection performance, but will increase maintenance costs. Is imported oil better than domestic oil? With the continuous development of domestic oil research and development, the performance of domestic oil products is no different from imported oil, and even exceeds imported oil in some fields. How to choose industrial gear oil? First, to consider the working conditions of industrial equipment, the basic performance of industrial lubricating oil and the main selection principle is viscosity, and to some extent, the specific type and viscosity of the lubricating oil used is determined by the ambient temperature. 1, in the medium speed, medium load and temperature is not too high working conditions, should choose medium viscosity lubricating oil; 2, under the conditions of high load, low speed and high temperature, high viscosity lubricating oil or oil with extreme pressure anti-wear agent should be selected; 3, in the condition of low load, high speed and low temperature, choose low viscosity lubricating oil; 4, in the wide, high, low temperature range, light load and high speed, and other special requirements of the working conditions, the use of synthetic lubricants. What mistakes should we avoid when changing oil? Color change equals failure? The color change of the oil is not equivalent to the change of the lubrication performance of the oil, because in most cases, it is impossible to ensure that the industrial gear oil is in a pollution-free environment, and the oil will bring impurities into the equipment or the environment during the lubrication protection of the machinery and equipment, thereby changing the color of the oil. The abnormal appearance of the oil means that the color of the oil is very obvious compared with the new oil after use (such as the yellow or brown of the new oil becomes black) or obvious sludge or granular matter can be observed in the oil. Therefore, the change in the color of industrial gear oil cannot be equivalent to the failure of oil lubrication performance. No damage to equipment, no replacement of oil? The damage of industrial equipment is often a process from small to huge, from slow to rapid, when the equipment occurs abnormal sound, indicating that the wear has been more serious, will face the risk of equipment maintenance, shutdown or scrap replacement. Industrial gear oil is the lubricating blood of industrial equipment, when the oil contains excess water, mechanical impurities or can not form a lubricating film, the oil should be changed in time to ensure that the equipment provides lubrication protection. How to define the oil change period? The determination of oil change cycle and oil change index is related to gear running-in condition, gear load, gear oil type and quality, and the importance of lubrication parts in mechanical equipment. In general, the gearbox with a small amount of oil can be regularly changed according to actual experience, the oil replacement cycle of the gearbox without water contact can reach 4000 ~ 5000h, the larger gear device is usually selected as a centralized lubrication system, due to the regular supplement of oil, often according to the deterioration of the oil, according to the quality of the oil change.

![]() January 14, 2024

January 14, 2024 The selection and replacement of industrial Gear Oil must avoid the 2 major misunderstandings!

The selection and replacement of industrial Gear Oil must avoid the 2 major misunderstandings!