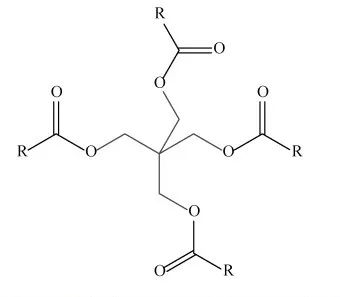

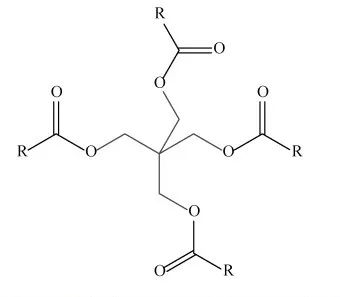

Ester synthetic oils are prepared by esterification and dehydration of acids and alcohols in the presence of catalyst. Their special molecular structure determines that they have excellent lubricity, low volatility and thermal oxidation stability. At the same time, it also has the advantages of biodegradation and renewable raw materials. These properties conform to the lubrication concept of "environmental protection and energy conservation", which makes them become new lubricating materials and widely used in many fields. They are a class of lubricating oils with great development potential and application prospects. According to the number and position of ester groups, synthetic esters can be divided into monoesters, diesters, compound esters and polyol esters. 1. Common polyol ester structure The most common polyol ester structure is neopentyl polyol ester, which is mainly obtained by esterification and dehydration of neopentyl alcohol and fatty acid. Pentaerythritol ester, trimethylolpropane ester and neopentyl glycol ester are representative of several neopentyl polyol esters.

The steric hindrance of the ortho quaternary carbon structure of the ester group enables such esters to have high free energy of thermal decomposition and excellent anti-oxidation performance, which can only be destroyed under high energy conditions. Therefore, the neopentyl polyol esters are also called hindered esters. Its thermal stability is the best among synthetic ester base oils. Its thermal decomposition temperature is about 50 ℃ higher than that of binary esters. The lubricating performance of neopentyl polyol ester is better than that of diesters, mineral oils and polyesters α Olefins (PAO). At the same time, it has good environmental protection, safety and reproducibility, and is often used as aircraft engine oil, refrigeration oil and high-temperature chain oil. In addition, since polyol esters have the advantages of good oxidation stability, less carbon deposition, and fire resistance, they are also used as Air Compressor Oil and fire resistant hydraulic oil. However, such esters also have certain disadvantages, mainly focusing on poor low temperature fluidity, poor water resistance, and easy decomposition under metal catalysis at high temperatures. 2. Application of polyol ester lubricating oil At present, BP, Mobil and China's 4050 and 4106 lubricating oils are widely used in aviation engine lubricating oils in the world, and the base oils of these lubricating oils are mainly polyol esters. Modern high-power aviation turbine engine requires lubricating oil to have better characteristics such as high temperature resistance, high speed resistance, heavy load resistance, long life, thermal oxidation stability, etc., so polyol ester with excellent viscosity temperature performance and high temperature resistance is the development trend of engine lubricating oil Base Oil in the future. At present, most ester oils are mixed with α- Semi synthetic internal combustion engine oil prepared by blending olefin oil or mineral oil can not only improve the performance of internal combustion engine oil, but also reduce the cost. At present, many precision instrument oils also use polyol ester lubricating oil. Because this kind of oil has good viscosity temperature property, low evaporation rate, high corrosion and pollution resistance, and good wear resistance, it can be used in a wide temperature range. 3. Conclusion and Outlook In the context of the decline of recoverable crude oil and the requirement of sustainable development. Polyol ester lubricating oils with excellent performance are developed with great prospects. Compared with mineral based lubricating oil, polyol ester lubricating oil has better lubricating performance, because there is strong adsorption between ester base and friction surface. The long carbon chain of fatty acid covers the friction surface, forming an interface oil film with better shear resistance, thus protecting the friction surface. Compared with mineral oil, the evaporation loss of polyol ester oil is smaller, and the larger the molecular weight of ester oil is, the smaller the evaporation loss is, and the longer the service life is, the more resources can be saved.

![]() January 22, 2023

January 22, 2023