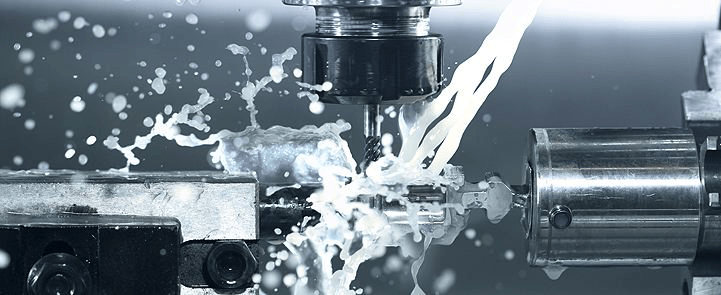

1. Reasonable use of cutting fluid Reasonable use of metal cutting fluid can effectively reduce cutting force, cutting temperature and thermal deformation of the processing system, which can not only ensure the processing quality of the workpiece, but also extend the tool life and reduce the processing cost.

The main functions of metal cutting fluid in mechanical removal are cooling, lubrication, cleaning and rust prevention. The effect of cutting fluid depends not only on the various properties of the cutting fluid itself, but also on the processing requirements, workpiece materials, tool materials, processing methods and other factors, which should be comprehensively considered, reasonably selected and correctly used. (1) Select according to processing requirements During rough machining, a large amount of cutting heat is generated due to large cutting amount. In order to reduce the cutting temperature, water-based cutting fluid with good cooling performance should be selected at this time. During finishing, the workpiece is required to obtain the best surface quality and smaller surface roughness value, so cutting oil should be used. (2) Corresponding to different processing methods In contemporary machining, there are various cutting methods. For example, turning, milling and drilling usually require efficient machining, so water-based cutting fluid should be selected; When broaching and cutting teeth, it is necessary to use more expensive and complex tools for processing. In order to ensure the processing quality and long service life of the tool, it is better to use oil-based cutting fluid. (3) Select according to different materials of workpiece and tool Tools and workpieces of different materials have different high temperature resistance, machinability, hardness, etc. At this time, different cutting fluids should be selected. For example, when machining gear and other workpieces with low hardness, it is necessary to use cutting fluid with high viscosity to prevent scratches on the gear surface; However, extreme pressure cutting oil or extreme pressure emulsion should be selected for cutting stainless steel and other difficult materials. (4) Select according to the characteristics of the machine tool For some efficient and valuable equipment, from the perspective of maintenance, oil-based cutting fluid with stable physical and chemical properties should be selected for processing to prevent metal parts from corrosion, rust, and obstacles to moving parts. However, for some open machine tools, oil-based cutting fluid is generally not suitable to avoid large amount of volatilization and dissipation of cutting oil. 2. Daily maintenance of metalworking fluid

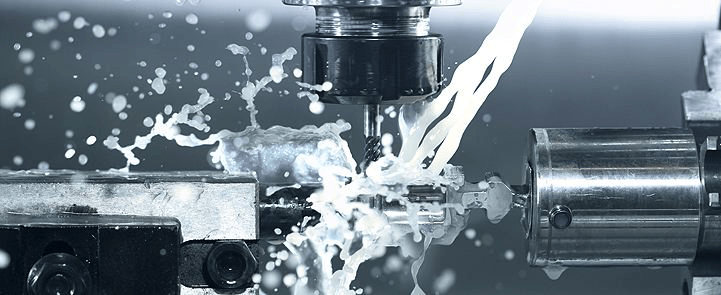

As a routine maintenance, the first thing to think about is the control of product concentration. Cutting fluid of any brand or model has the recommended concentration range of the manufacturer, which is not only related to the cutting fluid itself, but also directly related to the processing technology.

It is suggested that the concentration should be strictly controlled within the recommended range during the daily maintenance. For the processes with high requirements for finishing or processing quality, it should be appropriately increased by 1% - 2% on the basis of the manufacturer's recommended range. This can not only reduce the impact of the concentration fluctuation on the processing quality and tool life, but also effectively extend the life of the cutting fluid. However, the actual maintenance cost is not as much as expected. The reason is that most of the water evaporated during the processing process is water, so the concentration of liquid replenishment under normal conditions will be far lower than the recommended concentration. 3. How to reduce the fluctuation of cutting fluid concentration? First, the control of liquid level and concentration. (1) Maintain a reasonable liquid level. Generally speaking, the liquid level of the centralized liquid supply system is controlled between 60% - 80% of the tank capacity; The liquid level of single machine shall not be lower than 80% of the tank capacity. (2) Set the target value, that is, the median value of the concentration range; If it is lower than this value, liquid should be replenished; (3) When adding liquid, it is recommended to use a mixer. If there is no mixer, it should be added at the place with the maximum flow, so that the original liquid can be dispersed as soon as possible; Secondly, it is to monitor the pH value of the cutting fluid. Like human body temperature, too low or too high is harmful. Generally speaking, the optimal range of cutting fluid is between 8.8 and 9.5. However, the problem of cutting fluid is more "low burning", especially when the starting rate is not high in summer, the probability of pH reduction will be more. What if the pH value decreases? (1) If it is within the controllable range, the concentration can be appropriately increased by 1-2%, and the management of oil slick and regular circulation can be strengthened; (2) When the pH value is between 8.5 and 8.8, an appropriate amount of pH improver specified by the manufacturer can be added and the microbial content can be detected; (3) When pH<8.5, the cutting fluid will have a peculiar smell. At this time, it is necessary to carry out sterilization treatment immediately. At the same time, it is necessary to contact the cutting fluid supplier to find out the cause together and develop a reasonable solution.